Package Driving

To build a package on a winding machine two motion are basically involved package rotation & yarn traverse.There are two method of package driving

- Frictional or surface drive in which package is driven by frictional contact with a drum driven by a motor.

- Direct or spindle drive in which package is driven by mounting it on a spindle which is positively driven from the motor.

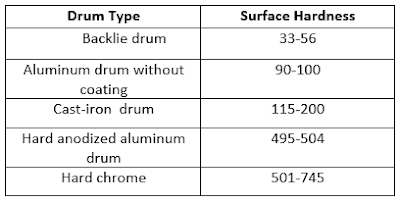

Surface Hardness of Various Drums

Winding

drum are usually cylindrical in shape. When a come is driven by cylindrical

drum, surface speed of drum and cone are equal only at one point. This point is

nearest to base of cone approximately at distance are third the come length its

base may not remain at some location through package build.

Suppose

cylinder drum driving a cone & drum. Diameter is 90mm and diameter of cone

at the nose and base at beginning of winding is 15mm to 60mm respectively.

Suppose is 45mm. assume that position of this point remain at the same through

package build upon winding of 15mm layer of yarn diameter of cone at the nose

and base become 45mm and 90mm respectively and diameter at point become 75mm 90

Π become

drum surface movement in one rotation.

Method of Yarn Traversing

Different

method of yarn traversing are

- Yarn

traversing with spirally slotted drum

- This the simplest method of yarn traversing consisting a drum which is provided with spiral slots.

- Yarn traverse to and fro following these slots the depth & width of the groove is so designed that the yarn traverse from one end to the other without any reversal in between.

- The drum also drives the package through surface contact.

- Yarn traversing with reciprocating guide using a grooved cam

- Principle of traverse stock variation angular position slotted breakage change with an increase in package diameter.

- Input from other source in from of a small to and fro motion is given which cause periodic shortening and lengthening of traverse stroke.

- Thus slotted bracket on one hand, change it angular position for traverse length reduction and on the other hand gets rocking motion which lengthens and shortness traverse stroke continuously.

- Principle of traverse stock variation angular position slotted breakage change with an increase in package diameter.

- Input from other source in from of a small to and fro motion is given which cause periodic shortening and lengthening of traverse stroke.

- Thus slotted bracket on one hand, change it angular position for traverse length reduction and on the other hand gets rocking motion which lengthens and shortness traverse stroke continuously.

- Yarn

traversing with counter rotating blades

- To archives very high traverse speed traversing system without reciprocating masses are attempted which are described in pattern.

- Traversing system with count rotating blade is widely used on commercial machine.

- Yarn

Traversing with slit drum

- A hollow drum carries 4 yarn enters the slit at lower end of slit driven passes through hollow portion and then emerge out from slit at upper end subsequently it is wound on the package.

- This method of yarn traversing is used on sewing thread winding m/c.

REF:

- fundamentals of yarn winding by Milind Koranne (Woodhead Publishing India in

textile)

DOWNLOAD

DOWNLOAD

0 Comments